Vertical Axis Wind Turbines

Vertical Axis Wind Turbines - VAWT

These turbines are optimised for tough and varied environmental conditions from high snowy altitudes to arid deserts and rugged terrain. As shown in any regional Wind Atlas, annual average winds will vary a lot from coastal to inland areas and are also affected by general topology

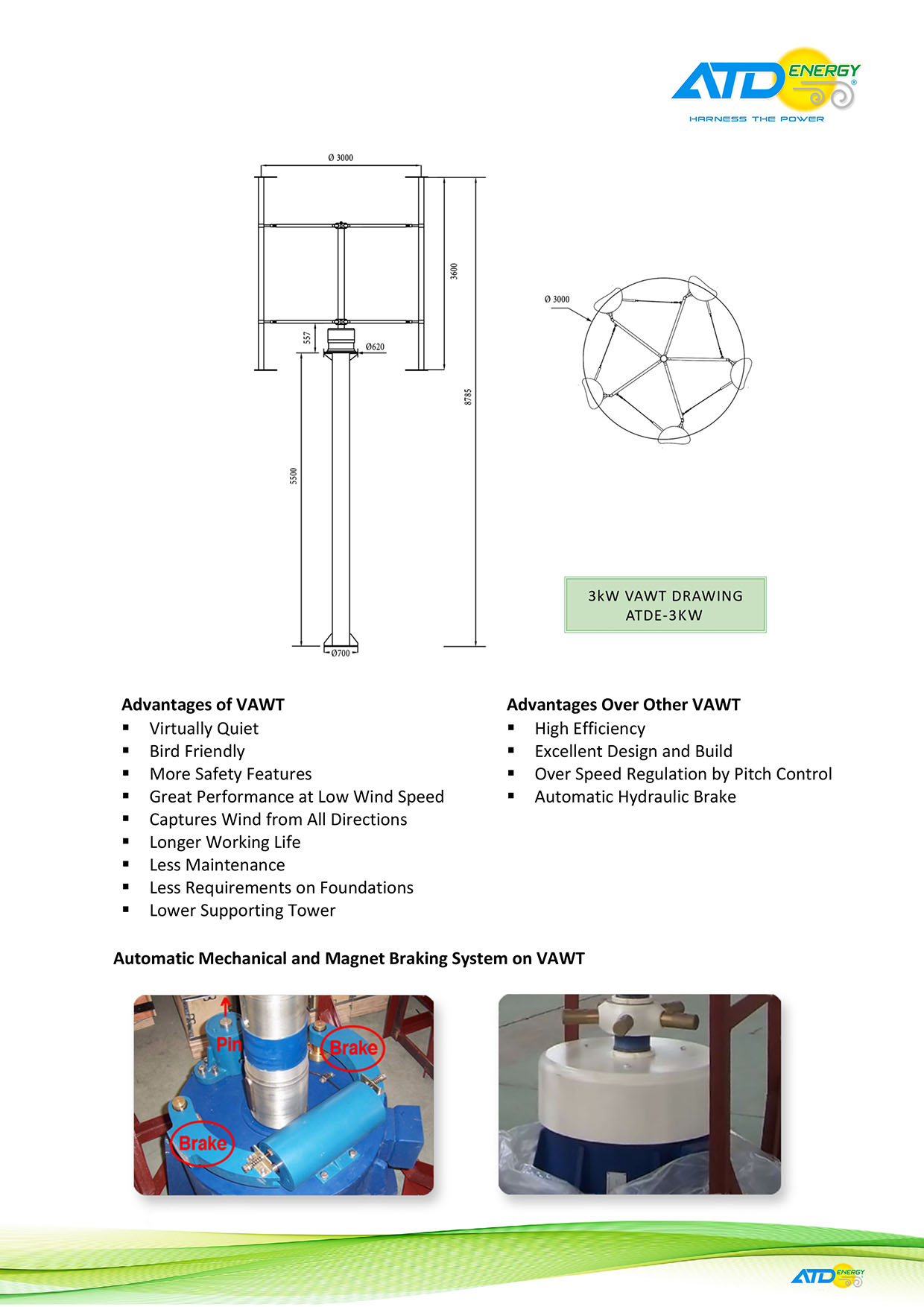

Key features of these turbines include:

- permanent electro-magnetic bearing generator

- active realtime variable pitch blades

- long operating life-span

- output efficiency over 24-hours

- virtually noise-free

- auto-break safety system

Huge advantages of VAWT energy production.

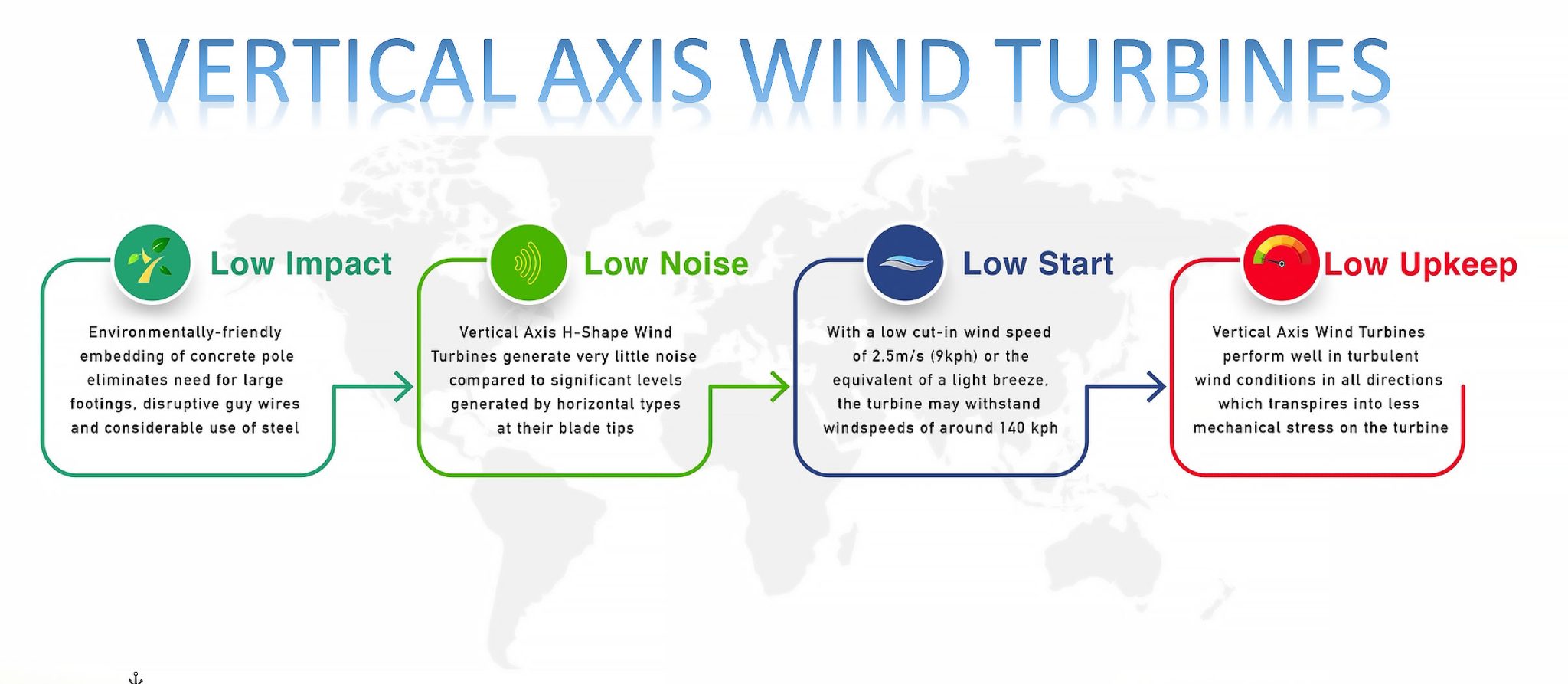

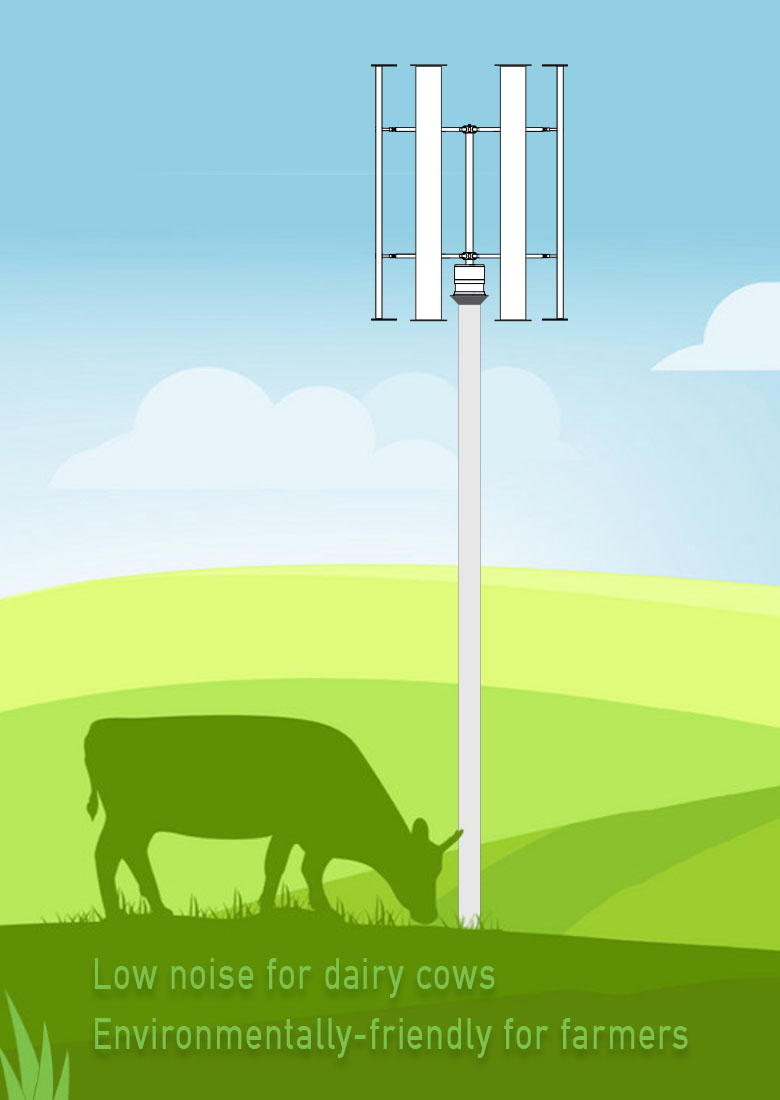

Vertical Axis Wind Turbines are ideally suited to wind turbulence as they require no orientation of the rotor and can work with winds from any direction. They are far less noisy than horizontal turbines and therefore will not disturb livestock or nearby occupants. High-end small-scale turbines are fast becoming a necessary addition to renewable energy systems. Turbines supplement solar energy limitations of sunshine and seasonal hours. Additional battery energy storage systems will provide a 24-hour power resource.

DESIGN, INNOVATION AND FUNCTION

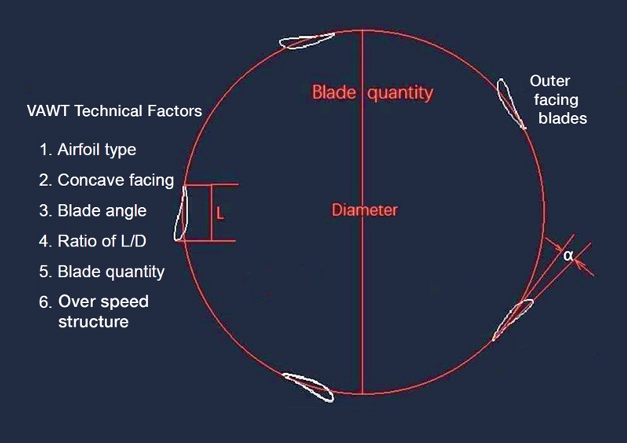

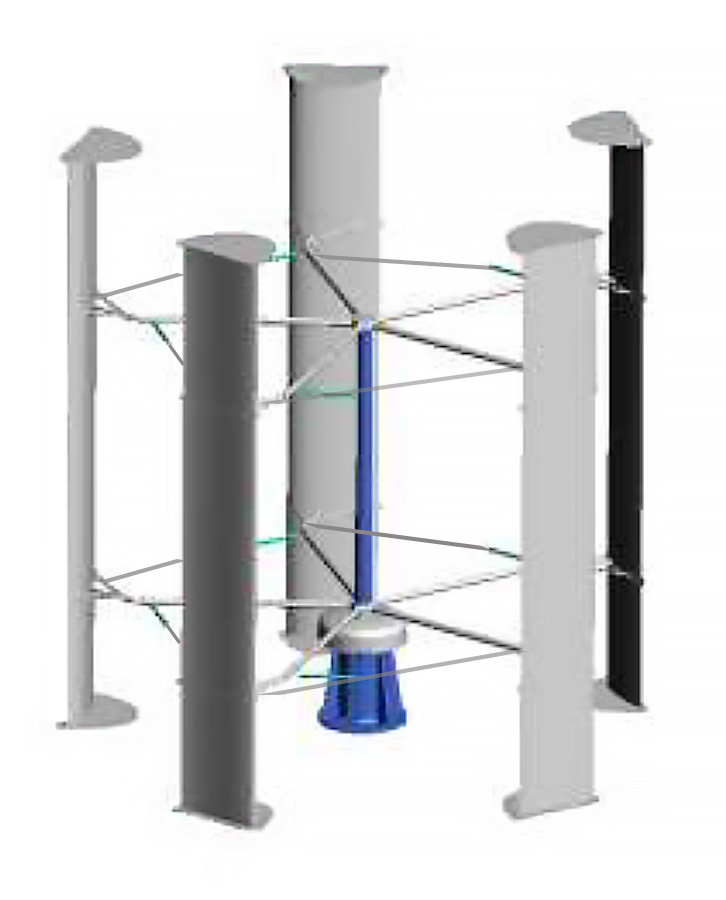

Aerodynamic Performance. Every shape and size of a surface such as an airfoil or blade, has a different set of characteristics. As they revolve around a fixed central axis, they are subjected to myriad wind force dynamics in addition to wind speed and direction. Their dimensions, quantity, diameter across the circumference, and internal volume or swept area, helps determine energy potential and performance.

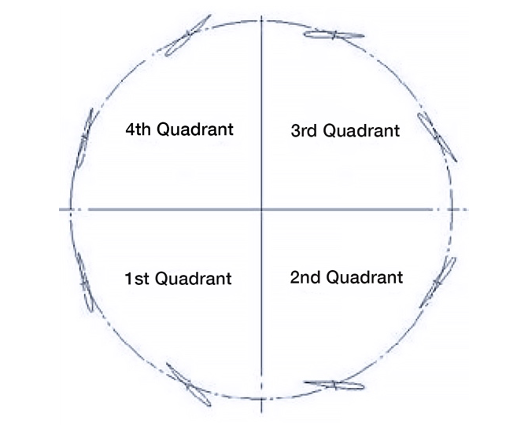

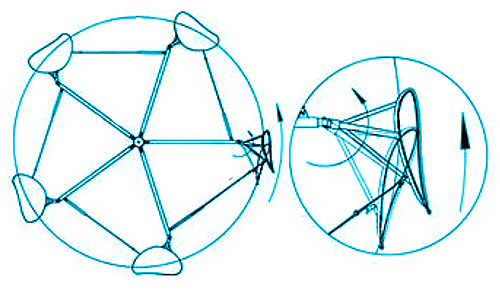

Variable Pitch Blades. This VAWT design incorporates a Positive Attack Angle Regulation which is controlled by the RPM – (variable pitch blades). This means that each blade has an optimal angle of attack at any position to maximise wind harvesting efficiency. After wind in the upwind direction passes through the first half of the VAWT, it becomes the downwind direction. Magnitudes of the power generated by the blades differ at different positions thereby optimising the performance at each instant.

Our VAWTs with their broad sweep, can be grouped in a proximity. Specifically, they are not encumbered by myriad guy wires that are generally considered unfriendly to grazing cattle; nor need protective surrounding fences that absorb valuable land requiring continual spraying to keep grass and weeds at bay.

VAWTs integrate perfectly with renewable systems, on or off-grid. Every site is uniquely varied in wind resources, so a site survey and energy assessment are necessary. This includes the geographic location, topology, obstructions and annual wind averages for the area.

Robust VAWT design for climatic challenges

Design innovation for Australian wind conditions centres around key issues such as:

- Low start-up or ‘cut-in’ speed – the capability to operate in minimal wind conditions like 3m/s (10.8km/h) and generate power

- Over-speed regulation – windmill capacity to maintain power generation in high wind conditions as opposed to full braking which generates nothing

- Auto and Mechanical Braking – both electrical and mechanical helps enable VAWT survival in severe weather conditions of perhaps 35-45m/s (126 -162km/h)

- Ease of maintenance and serviceability – various tower heights and types, and structural design of the VAWT, enables easier access by cranes or boom-lifts.

Adjusting the blade angle in real-time per rotation, enables the blade to obtain the best angle at any azimuth, increasing the driving torque in both upwind and downwind positions. This means that each blade can supply power from any position using positive attack angle regulation.

Our VAWTs are noise-free and safe due to their low rotational speed, higher torque, and box girder structure of the blades. VAWTs have less impact on the grid because their rotational speed is less sensitive to changes in wind speed, and their rotational inertia is bigger, whereby their output voltage only fluctuates mildly.

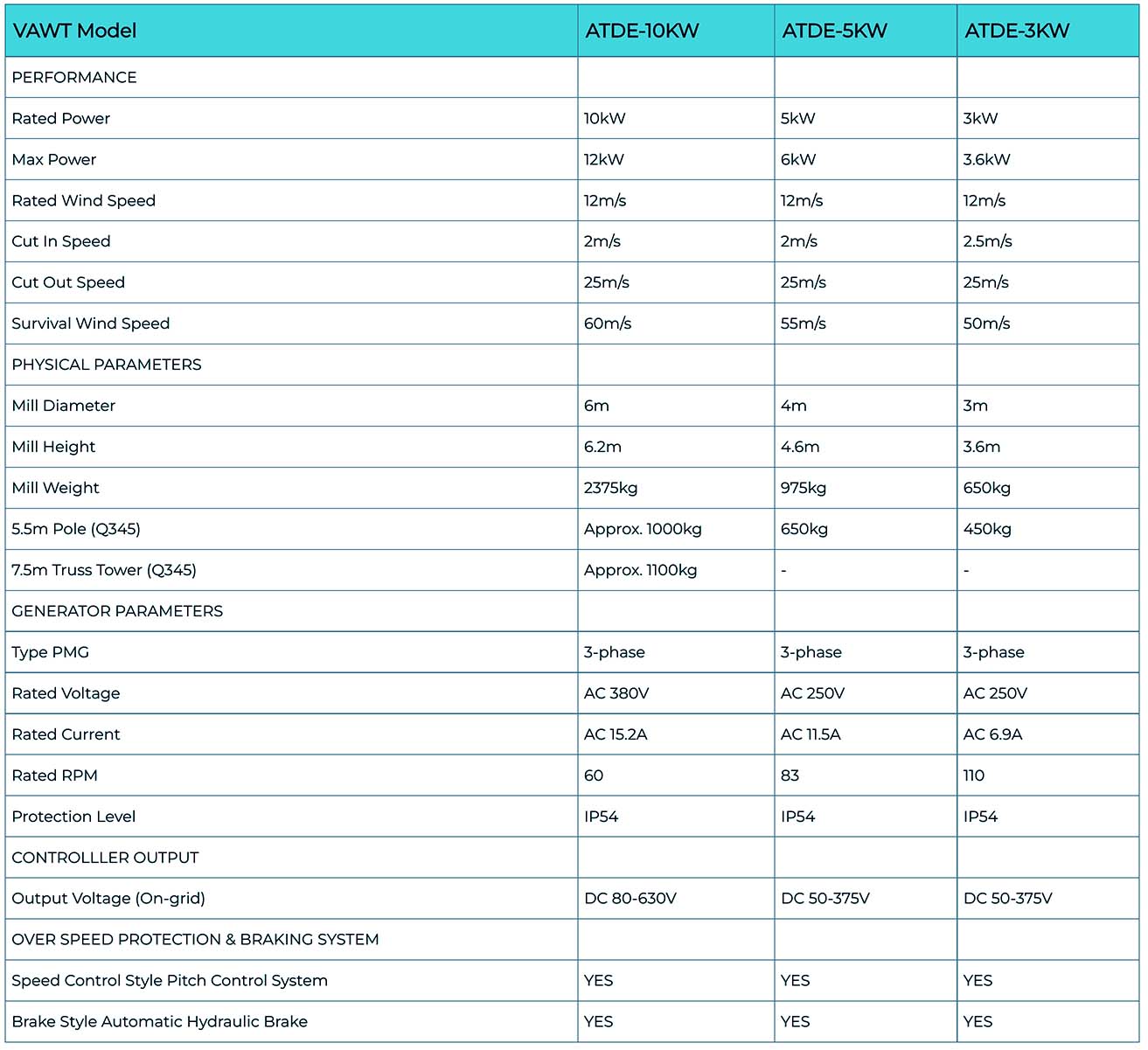

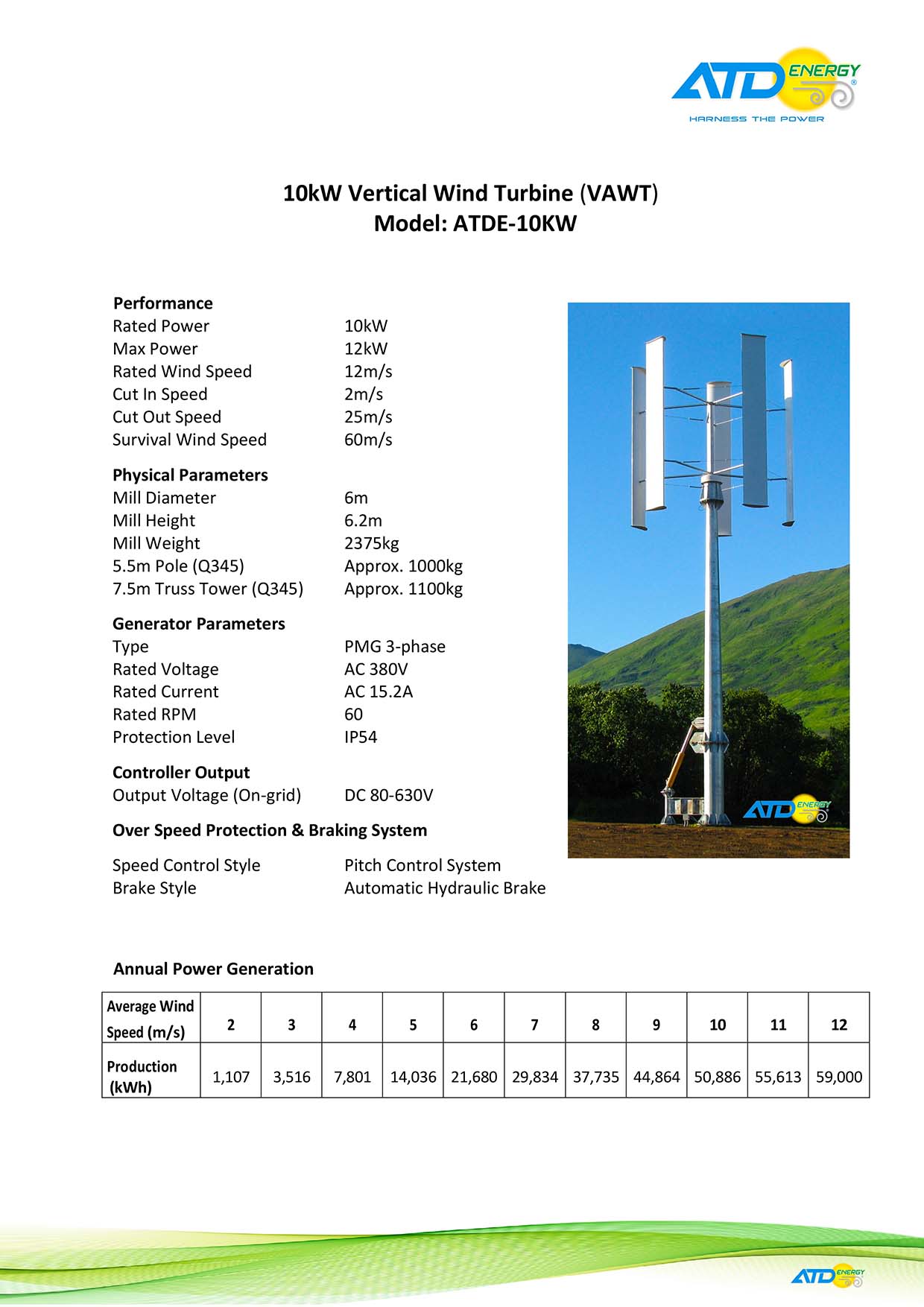

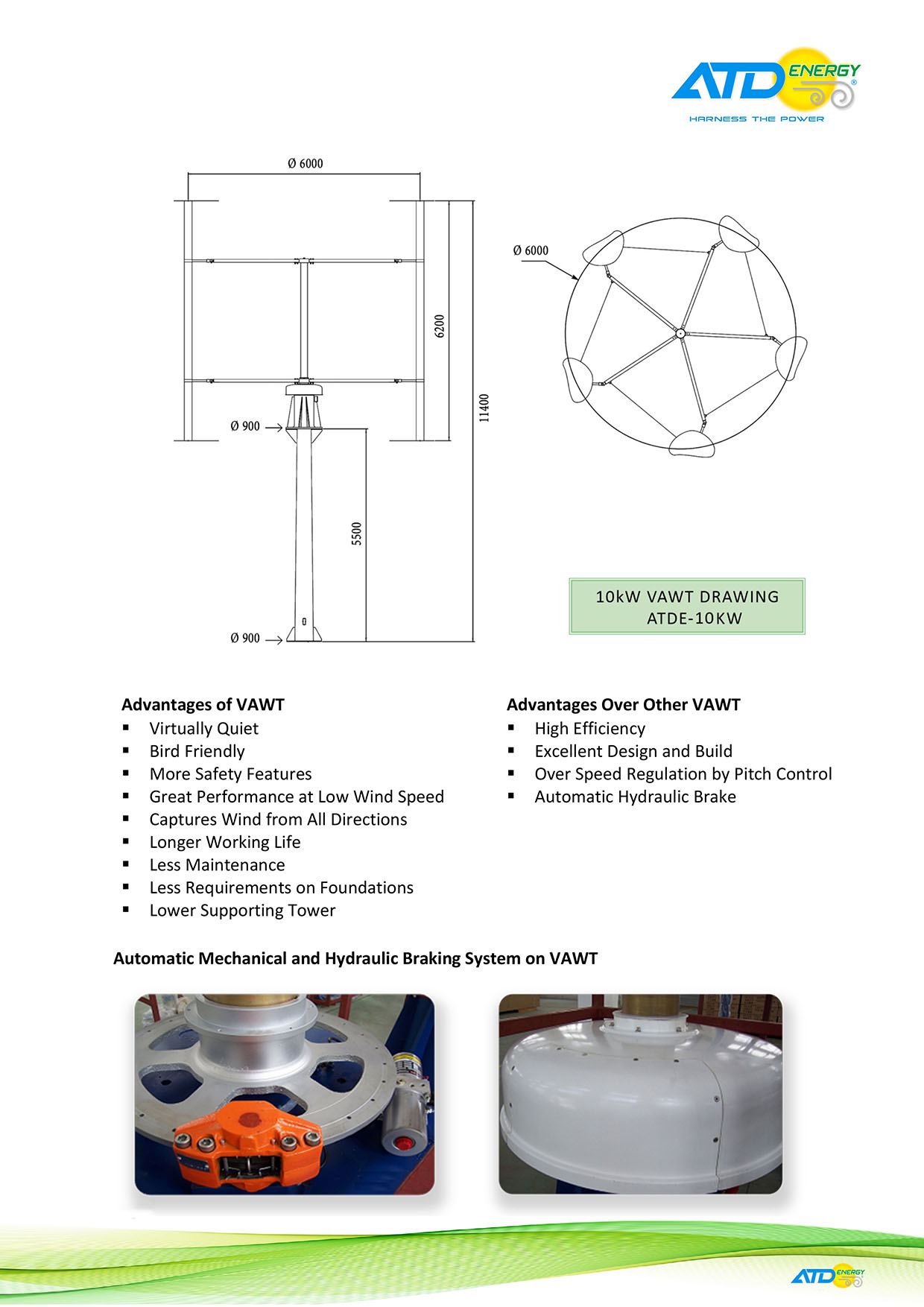

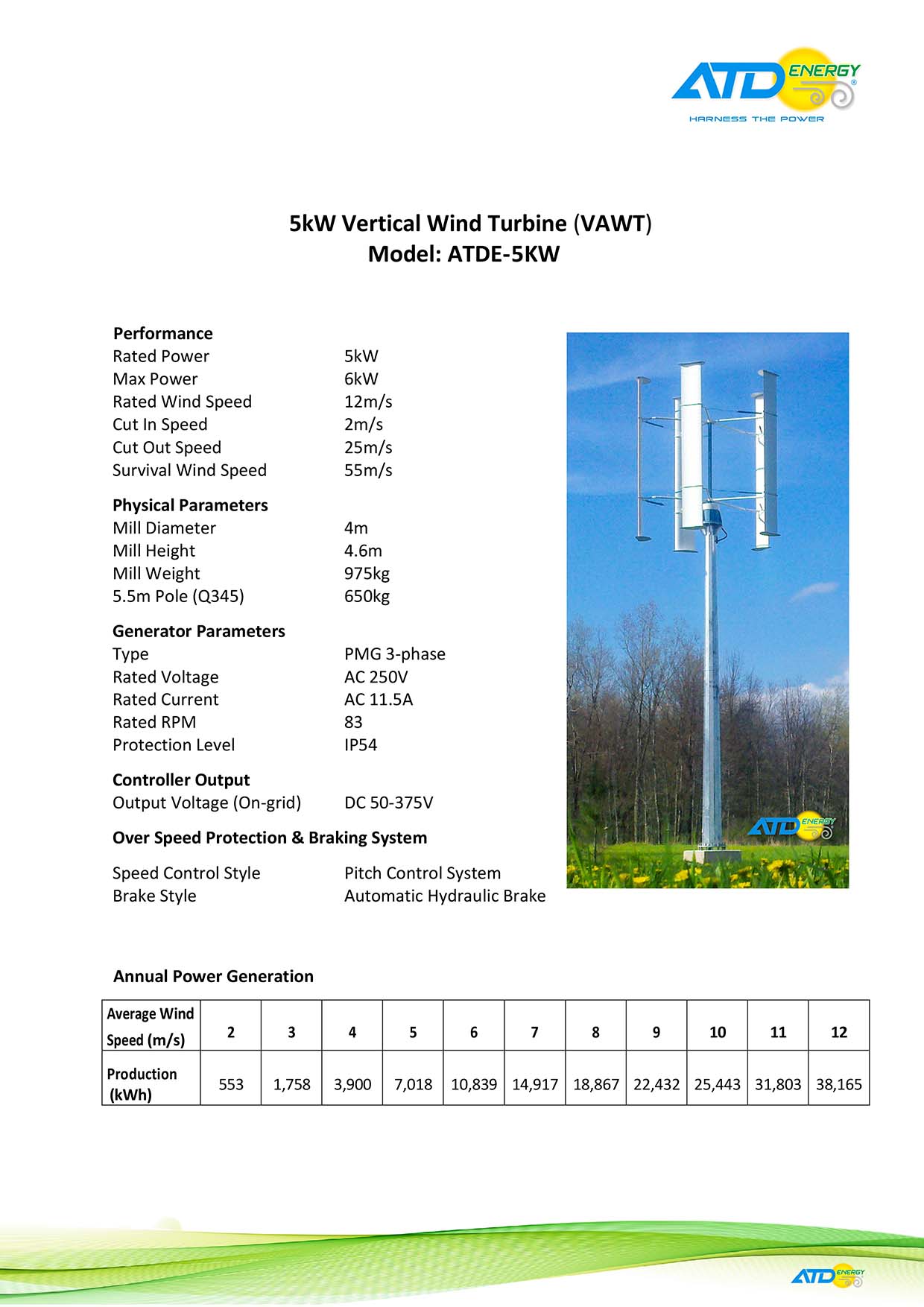

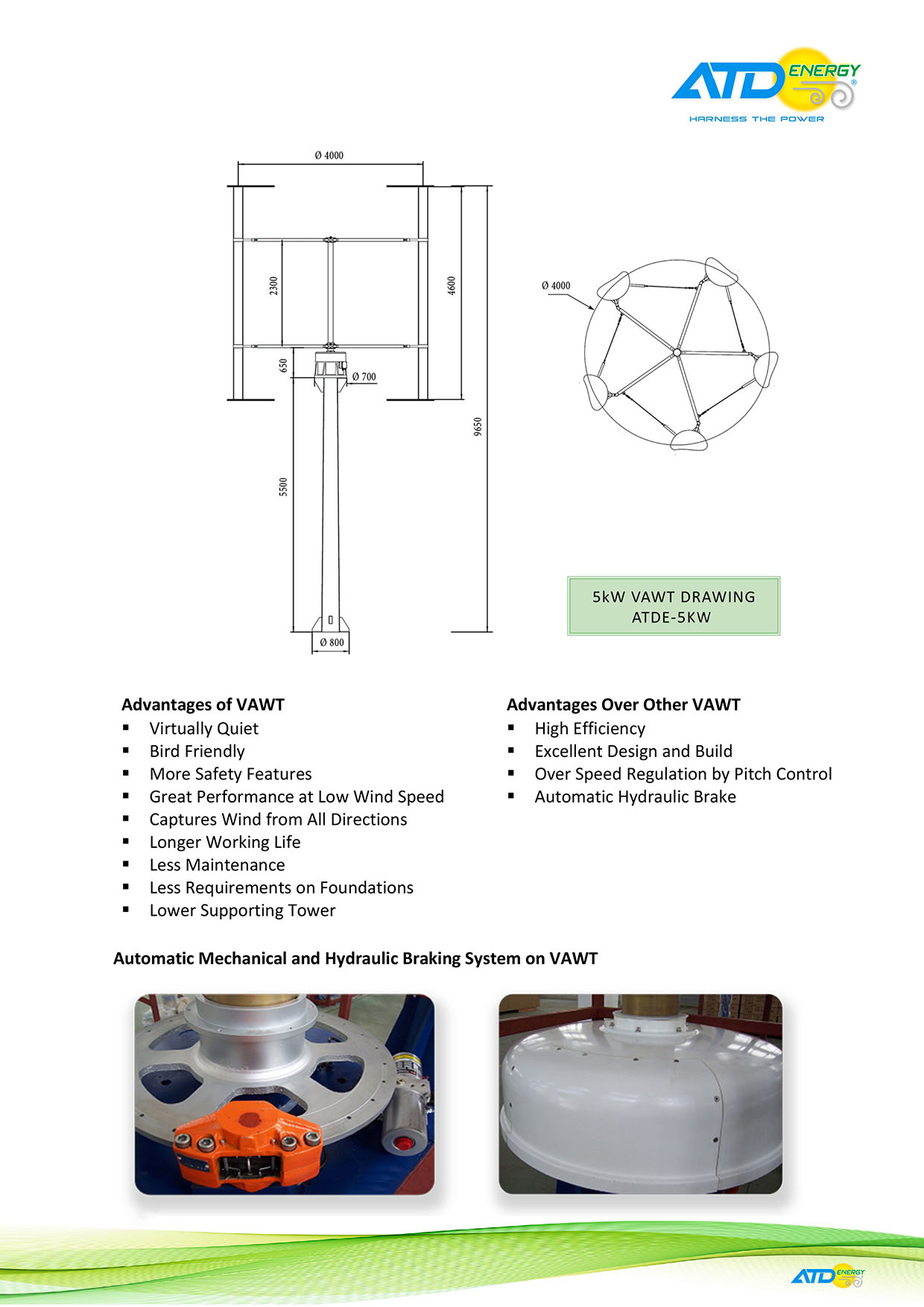

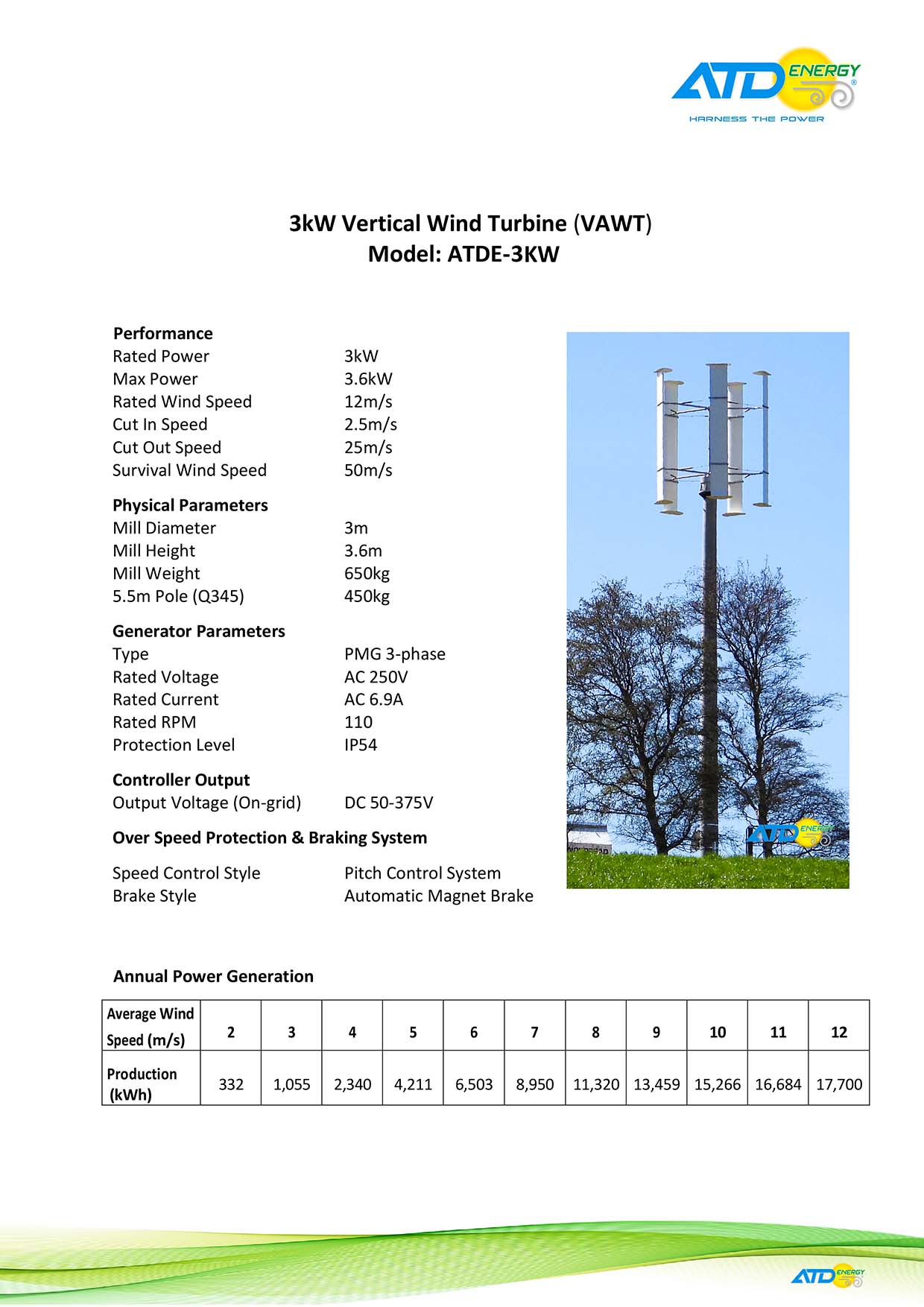

Optimised for tough Australian conditions, they combine numerous curved aerofoil blades connected to a centrally mounted permanent magnet generator. Mounted high on a 12-metre pole they require a low start-up torque, or light gentle breeze to drive them and generate power. ATD Energy currently provide these in 3, 5 and 10kW models to suit any environment from rural, to industrial and commercial locations.

A lot more attention is now being focussed on VAWT advantages such as their excellent aerodynamic performance, higher wind energy utilization rates and wider working wind speed range.

ATd Energy 3kw vertical axis wind turbine

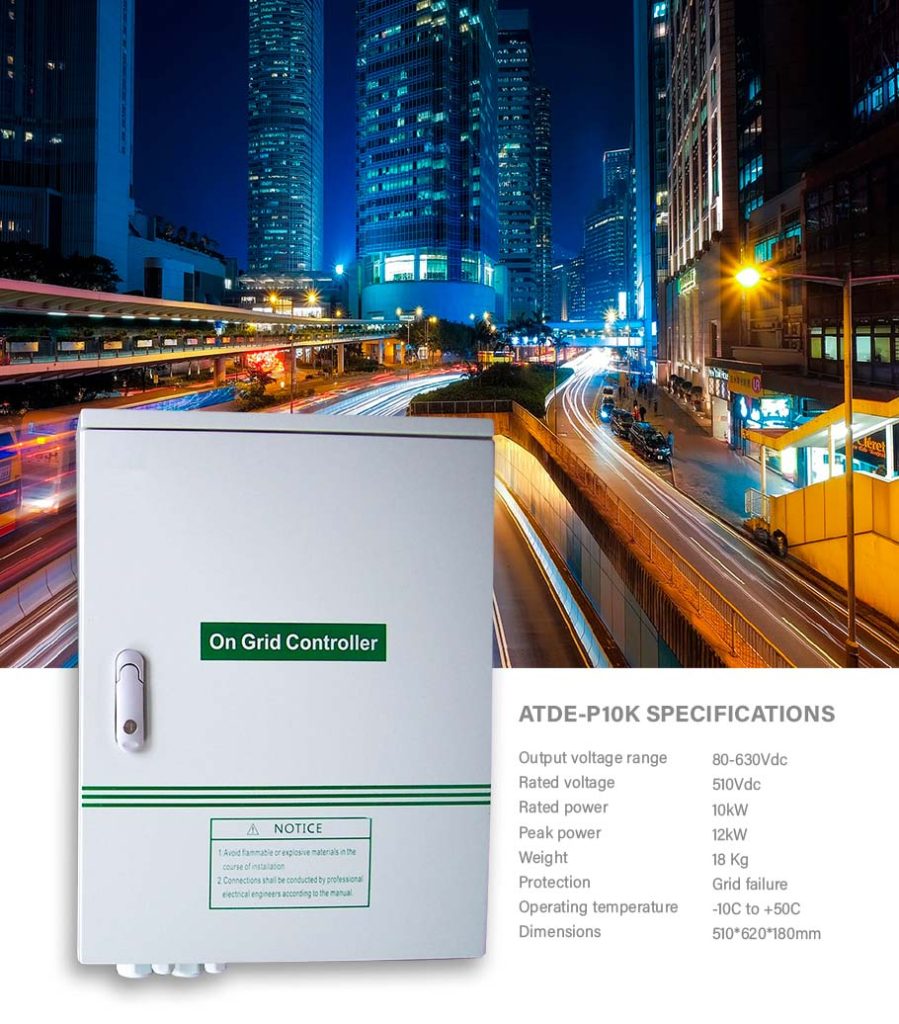

Integrated Power/Wind Controller

This Power, or Wind Controller, is designed to work as an integrated system with the VAWT. It essentially manages the turbine and applies automatic braking when the RPM reaches the limits of the safety levels caused by high-velocity wind conditions.

All VAWT installations and maintenance MUST be carried out by qualified personnel with appropriate certifications – both electrical and engineering, to avoid damage, injury, electrocution or any other high life risks.

The Controller has three-phase AC inputs and one-phase DC output, and differs slightly for on-grid or off-grid applications. Each controller is equipped with a Microchip MCU and static switch, and various mechanisms to protect the wind generator.

Frequently Asked Questions - FAQ

Because of the lack of design theories and design basis, many companies apply the experiences of horizontal turbine design to vertical turbines. And some companies design vertical turbines based on their own preference. Most of the vertical turbines designed in this way are drag-type.

Vertical wind turbines could be categorized into drag-type and lift-type. Many drag-type vertical turbines or drag lift hybrid type turbines can easily rotate because of aerodynamic design but generate very little electricity or none at all. Although some vertical turbines are lift-type, the designers don’t master the characteristics of vertical turbines; they have chosen the wrong airfoil and other important parameters. Consequently, the aerodynamic performance is very low. For some lift-type turbines, the RPM of the turbine windmill and generator don’t match, which would cause less electricity to be generated as well. These are some major reasons that many vertical turbines don’t generate electricity.

A good vertical turbine must have good performance in power generation – particularly at low wind speeds. And must be able to work in a wide range of wind speeds similar to large horizontal wind turbines.

Additionally, good methods of over-speed control and automatic mechanical braking are necessary features of a good vertical turbine. A generator short circuit is quite common for braking, but it is not a good solution. It causes the degaussing of the permanent magnet generator and eventually shortens its lifespan.

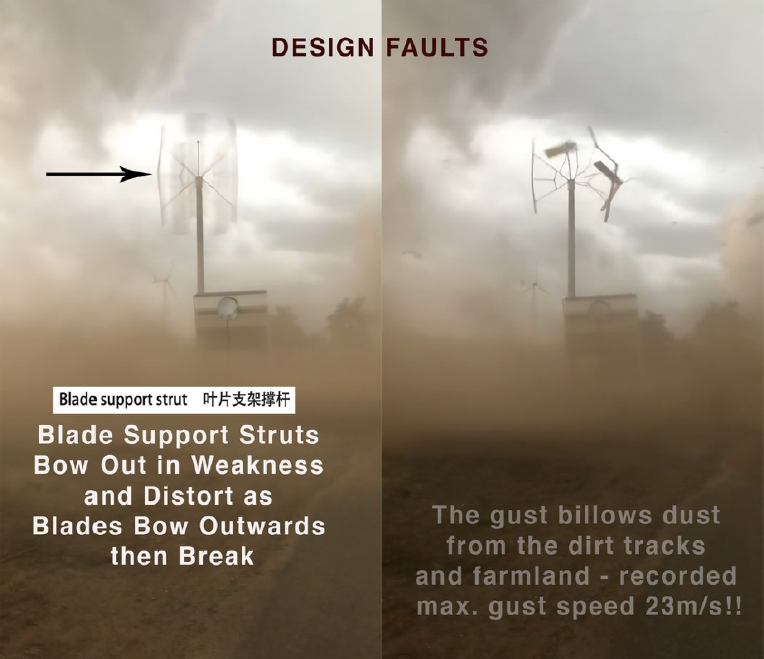

As wind power is proportional to the cube of wind speed, a doubling of wind speed results in a multiple of 8 times the wind energy. Vertical turbines can’t yaw like horizontal ones and therefore if a vertical turbine does not have pitch angle control for over-speed regulation, and automatic mechanical braking, it could break up and collapse very easily, even when the wind is not that strong.

For example, the images below show the poorly designed Heng Feng brand with fundamental design flaws and in particular, the central struts – as highlighted in these video frame excerpts.

A vertical turbine must have an electricity generation performance comparable to large horizontal turbines; have pitch control, over-speed regulation, and an automatic mechanical brake. Otherwise, it has no commercial value.

Our vertical turbines have very high system efficiency, which is comparable to that of large horizontal turbines; particularly in low wind speeds such as 3 – 8m/s. Our turbines perform even better than large horizontal turbines, as shown by the real-time monitoring of our operating turbines.

Our wind turbines start turning and producing electricity in just over a 2m/s wind reaching a rated power output of around 12 m/s (around 28 mph). The energy generated rises dramatically with wind speed, as a doubling of wind speed results in a multiple of 8 times the wind energy. Ensure you have a qualified electrical engineer design and install your system to Harness The Power.

No. Our turbines have pitch angle control so they never exceed their design rotation speed. The automatic brake will start when the wind speed reaches 25m/s, so the turbines are worry-free even in very strong wind.

Yes. They can be installed on various roofs. Depending on the material and structure of the roof, it is generally necessary to design and tailor the foundation of the turbine for overall safety compliance.

Yes. We have a product for direct heating. The heater is directly connected to the controller of the turbine. This system doesn’t need batteries or an inverter. This is an application of wind turbines at a very low cost. It is perfect for people living in colder regions.

Yes. This is referred to as a hybrid system. There are numerous configurations that can be applied.

Our small vertical wind turbines are designed based on the safety standard of megawatt horizontal turbines with a survival wind of up to 55m/s, so they are heavier than many other vertical turbines. Our small turbines also perform very well at low wind speeds. Overall, the weight depends on your perspective.

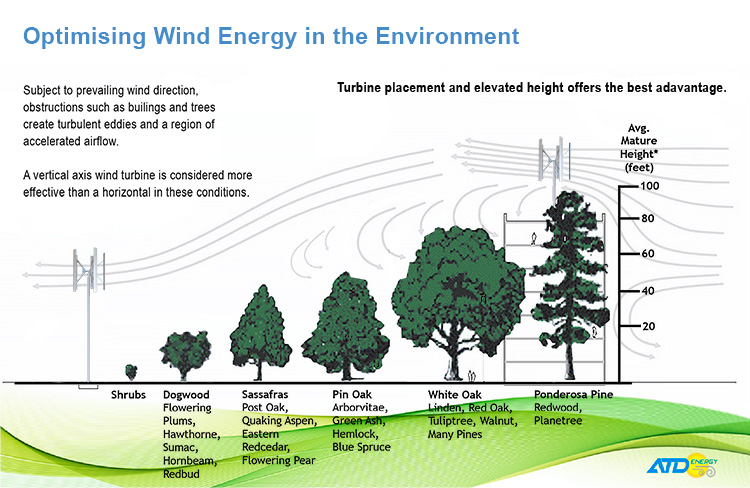

Careful consideration must be given to the siting of the turbine to get the best performance and reliability from it. Output from a wind turbine is sensitive to wind. It is important that turbines are sited away from obstructions such as tall trees and buildings. Wind speed also increases with height above ground so it is best to have the turbine mounted on a tower/ pole of at least 9 or 10 meters. For practicality, turbines should be located in close proximity to the user, though at a distance from local obstructions. Or alternatively, use a taller tower to ensure that the turbine is well above the obstructions.

It is not always the case. The voltage of the generator must reach the minimum input voltage of the inverter or battery charging voltage, for it to be generating power. Most small-scale turbines are inefficient due to poor design characteristics or other fundamental flaws.

Most horizontal turbines create noise; some are quite disruptive – particularly to local residents at night.

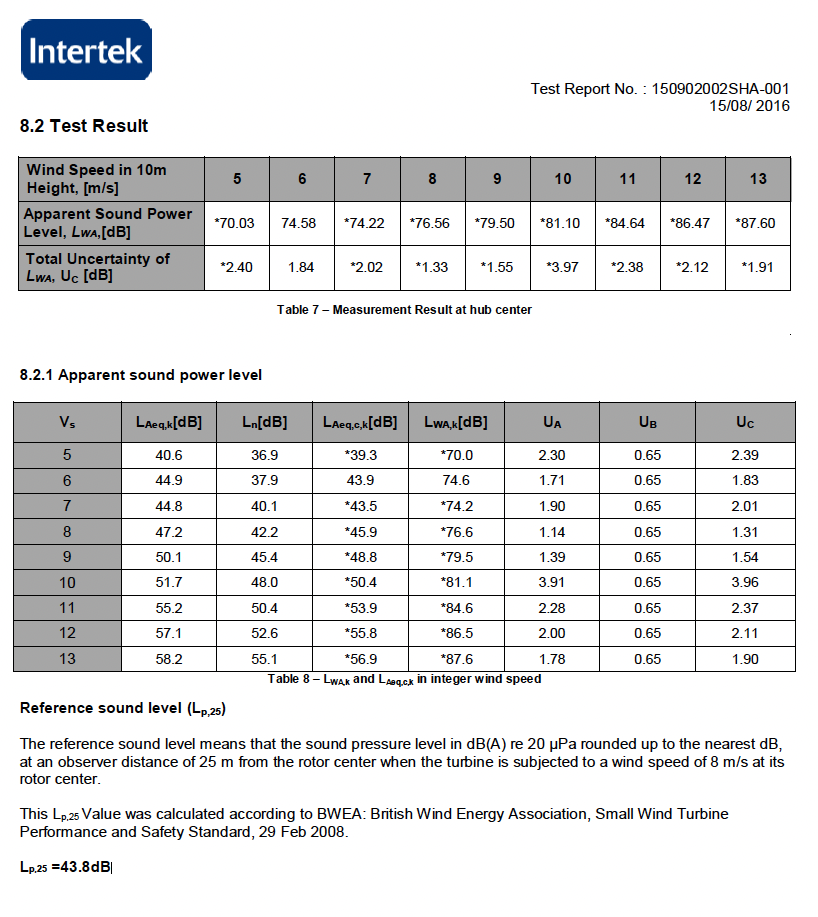

Our vertical turbines are well-designed and have very little noise. Intertek, a leading international wind calibration agency measured our 10kW turbine at an average of 43.8dB only – which is equivalent to being inside a library.

Vertical wind turbines do not disturb cows which is why they are very popular with farmers. They take up very little space with no intrusive guy wires and do not generate noise that disrupts grazing livestock. As farmland and facilities consume a large amount of electricity, vertical turbines play an important role in energy production and cost reduction.

No. Vertical turbines do not hurt birds or bats.